Starting a product business traditionally requires a crushing upfront investment. Minimum order quantities of 500-1,000 units. Warehouse space for inventory. Capital tied up in products that might not sell. The risk has kept countless entrepreneurs from ever launching their ideas.

Small batch 3D printing changes this equation completely. You can now produce 5, 20, or 50 units of a product—testing real market demand before committing to mass production. According to Shopify's research on product development, reducing upfront inventory risk is one of the most critical factors for new business survival.

Traditional manufacturing creates an impossible catch-22 for new businesses. You need sales to prove your concept works, but you need thousands of units (and thousands of dollars) before you can make your first sale.

The traditional manufacturing problem:

Most factories require minimum orders of 500-1,000 units, which means $5,000-$50,000 in upfront costs before you've validated your product. Lead times of 8-16 weeks delay your ability to test and iterate. Tooling and mold costs add another $2,000-$10,000 to your startup expenses. Industry data from Thomasnet confirms these barriers are the primary obstacle for new product launches.

Once you've committed to these minimums, you're stuck with your design—even if customers want modifications. Unsold inventory drains cash and occupies expensive storage space. The financial risk forces many entrepreneurs to abandon promising ideas.

How small batch 3D printing solves this:

Print exactly the quantity you need, whether that's 1 unit or 100. Test your design in the real market before scaling to mass production. Iterate quickly based on customer feedback without wasting previous inventory. Fulfill pre-orders and crowdfunding commitments without factory minimums.

Launch new product variations without retooling costs. Keep zero inventory by printing on-demand as orders come in.

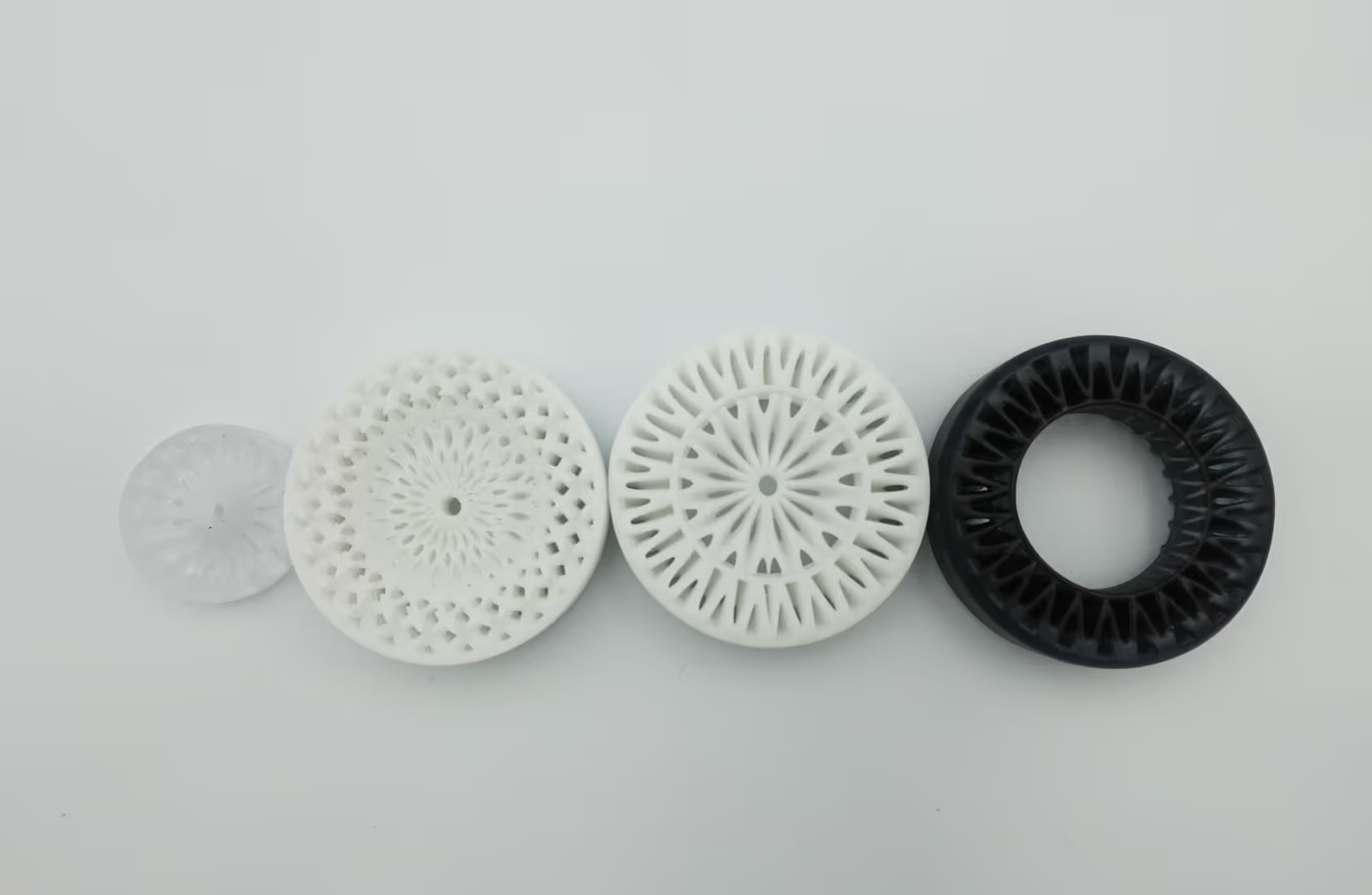

Not all 3D printing is created equal. Consumer FDM printers that cost a few hundred dollars produce visible layer lines and rough surfaces that look amateurish. Professional SLA printing delivers quality that matches or exceeds traditional manufacturing.

What makes SLA printing different:

SLA technology uses a precision laser to cure liquid resin layer by layer, creating incredibly smooth surfaces with fine details. The resolution is measured in microns—far more precise than FDM printing. Parts come out with a professional finish that customers expect from retail products. Learn more about professional 3D printing technologies and how they compare.

Womp's SLA printing service uses industrial-grade equipment to produce consistent, high-quality results. You get the same material properties and finish quality whether you print 1 unit or 100 units.

Material options for professional products:

White prototyping plastic delivers a stark white, smooth finish that looks premium and professional. It's affordable enough for testing while maintaining the quality needed for customer-facing products. This material works perfectly for functional prototypes, market testing, and limited production runs.

Clear resin creates crystal-clear transparency ideal for display pieces, light-based products, or designs where seeing internal mechanisms adds value. You can choose between matte finishes for softer aesthetics or glossy finishes for maximum clarity.

Both materials offer professional durability and presentation quality that your customers will perceive as valuable.

Entrepreneurs across industries are using small batch 3D printing to launch products that would have been impossible with traditional manufacturing minimums.

Product testing and validation:

Create 10-25 units of your design to test with real customers before committing to large production runs. A jewelry designer can offer 5 different pendant styles to gauge which designs generate the most interest. A home goods entrepreneur can test whether customers prefer one size or need multiple options.

This real-world feedback is invaluable—you learn what customers actually want to buy, not what you think they should want.

Crowdfunding and pre-orders:

Crowdfunding platforms have democratized product launches, but fulfilling backer rewards still requires production capabilities. According to Kickstarter, fulfillment is one of the most challenging aspects for first-time creators. Small batch 3D printing lets you fulfill campaign commitments without factory minimums.

Print exactly the number of units your backers ordered. Handle multiple product tiers without separate tooling costs. Ship rewards on schedule without waiting for factory production slots. Add stretch goals and variants as your campaign grows.

Limited edition releases:

Some of the most successful product strategies involve creating scarcity and exclusivity. Small batch production makes limited releases economically viable. This works especially well for custom 3D printed gifts and collectible items.

Launch seasonal collections with just 20-50 units of each design. Create numbered limited editions that command premium pricing. Test special colorways or variants without committing to large inventories. Build anticipation for your next small drop.

Made-to-order business models:

The most capital-efficient businesses carry no inventory at all—they print products only after customers order them. This model is now accessible to entrepreneurs through on-demand 3D printing. Harvard Business Review research shows that on-demand manufacturing significantly reduces financial risk for new businesses.

Customers order through your website or store. You submit their order to print within 24 hours. The finished product ships directly to them within 3-7 days. You never touch inventory or manage storage.

This approach works especially well for customizable products, personalized items, and designs with many variations.

Understanding the economics of small batch 3D printing helps you price products appropriately and manage margins as you scale.

How pricing works:

3D printing costs are based primarily on material volume—the physical amount of resin used to create your object. A small pendant might use $2-5 in material, while a larger decorative piece could use $15-30.

Womp shows you exact costs before you order, and you can optimize pricing in real-time by adjusting size or hollowing your design to use less material.

Optimizing costs:

Size directly impacts cost—a model that's 30% smaller uses roughly 70% less material. Hollowing objects can reduce material usage by 50-80% while maintaining structural integrity. The print mode shows you wall thickness and structural health to ensure hollow designs will print successfully.

For products you'll produce repeatedly, spending time optimizing the design pays dividends across every unit you make.

Break-even analysis:

Small batch printing costs more per unit than mass production, but breaks even much faster because you avoid massive upfront investments.

Printing 50 units at $8 each costs $400 total—no tooling, no minimums, no wasted inventory. If your product sells at $35, you're profitable after selling just 12 units. The remaining 38 units are pure profit, and you've validated your concept with manageable risk.

Compare this to manufacturing 1,000 units with $3,000 in tooling and $4 per unit—you need to sell 350 units just to break even.

Creating designs that print successfully and look professional requires understanding a few key principles. Womp makes this easier by showing you potential issues before you order. For comprehensive guidelines, check out our 3D printing design tips.

Wall thickness requirements:

All printed objects must have walls at least 1.2mm thick to print successfully and maintain structural integrity. Womp's x-ray view lets you see wall thickness throughout your model, highlighting areas that are too thin.

For products that customers will handle regularly, consider 2-3mm walls for added durability.

Size limits and considerations:

Prints must be at least 10mm × 10mm × 10mm—smaller objects become too delicate to print and handle. Maximum sizes depend on the print bed, but most product designs fit comfortably within the available print volume.

Womp's print mode shows you exact dimensions and lets you scale designs up or down while seeing how size changes affect cost.

Hollowing for cost savings:

Solid objects use significantly more material than necessary. Hollowing creates a shell with internal air space, dramatically reducing material costs while maintaining the external appearance.

For hollow objects to print successfully, they need drain holes at the lowest points to allow uncured resin to escape during printing. Womp helps you identify where drain holes are needed and ensures they're properly placed.

Design for assembly:

Complex products often work better as multiple pieces that attach together rather than single prints. This approach offers several advantages.

Print complex geometries that would be impossible as single pieces. Replace specific parts if they break without reprinting the entire object. Use different materials for different components. Reduce print failures by breaking complex designs into simpler parts.

Design simple connection methods like snap fits, pegs, or glue surfaces that work reliably with 3D printed parts.

Womp integrates design and production into a single workflow, eliminating the complexity of working with separate modeling software and print service providers.

From design to physical product:

Design your product directly in your browser using Womp's intuitive 3D modeling tools. No downloads, installations, or expensive software licenses required. When your design is ready, click the print button to enter print mode.

Select your material, adjust sizing if needed, and choose solid or hollow printing. Womp shows you exactly how your finished product will look and calculates precise costs. Add your design to the cart and check out—your print begins production within 24 hours.

Finished products are cleaned, cured, and shipped within 3-7 business days depending on your location.

Design iteration workflow:

The fastest path to a successful product involves printing, testing, and refining your design multiple times. Womp makes this iteration cycle fast and affordable. Learn more about streamlining product design with 3D modeling.

Print your first design at a smaller size to reduce testing costs. Test the design physically—how it feels, functions, and looks. Make adjustments in Womp based on what you learned. Print the updated version and repeat until you're satisfied.

This iterative approach costs a fraction of traditional prototyping and happens in days instead of months. Research from MIT shows that rapid prototyping dramatically increases product success rates.

Scaling from testing to production:

Once you've validated your design with small batch printing, you can scale production in two ways. Learn more about rapid prototyping services for faster iteration cycles.

Continue printing on-demand through Womp for capital-efficient made-to-order operations. This works well for products with many variations, limited editions, or when you want to avoid inventory risk.

Alternatively, use your proven 3D printed products as perfect samples for traditional manufacturing quotes. You've already proven market demand, refined your design through real-world testing, and have physical samples to send to manufacturers.

Your 3D printing phase has eliminated the risk from mass production—you're no longer guessing whether customers will buy your unproven concept.

The entrepreneurs who succeed with small batch 3D printing share common approaches that maximize the advantages of this production method.

Test multiple designs simultaneously:

Instead of committing everything to one design, print 3-5 variations and test them all. A jewelry maker might print pendants in three different styles, at two different sizes, offering six total variations. Customer preference data reveals which designs deserve further investment.

This portfolio approach spreads risk and often reveals unexpected winners.

Build pre-launch waitlists:

Before printing any inventory, validate interest by collecting email addresses from potential customers. Show high-quality renders of your product and explain your launch timeline. When you reach 50-100 interested people, print a small batch and email your list when products are available.

This approach guarantees sales for your first production run.

Document your process:

Customers love seeing products come to life. Share progress photos of your designs, explain your printing process, and show the journey from digital model to physical product.

This content builds anticipation, establishes authenticity, and often generates more interest than traditional product marketing.

Embrace iteration publicly:

Don't hide the fact that you're refining your products based on feedback. Customers appreciate entrepreneurs who listen and improve.

When you launch version 2.0 of a product with improvements based on customer input, you're demonstrating responsiveness that large manufacturers can't match.

The barriers to launching physical products have never been lower. Small batch 3D printing eliminates the capital requirements and risk that traditionally prevented entrepreneurs from bringing their ideas to market. Many creators are even turning 3D modeling into profitable side businesses.

You don't need manufacturing expertise, extensive capital, or industry connections. You need a product idea and the willingness to test it with real customers. Entrepreneur Magazine emphasizes that testing with minimal investment is the smartest way to launch product businesses in 2025.

Womp provides the complete toolkit—intuitive design tools, professional printing service, and transparent pricing—all integrated into a single platform that works entirely in your browser.

Ready to launch your product? Create your free Womp account and start designing today. Your first small batch could ship within a week.

Learn more: